Automatic Laminating Machine

Sunfung offers a rich selection of print finishing products that are suited for any cuttings, creasings, laminatings and other applications. Our team works with you in finding the right print finishing solutions for your business.

Talk to Our Expert

*We respect your confidentiality and all information are protected.

You Will Benefit from

Explore Reliable Automatic Laminating Machines

Reinforce your fragile papers, posters and vinyl sheets with industrial laminators that promise superior quality and stimulate production. We at Sunfung, offer a wide range of heavy duty laminating machines that includes the industry-favorites roll laminator and SF-390 laminator.

Models | SF-390 | SF-390A | SF-540A |

|---|---|---|---|

Dimension (W*L*H) | 1730*760*1420 mm | 1730*800*1480 mm | 1500*1150*1350 mm |

Laminating Sepeed | 0.5 ~ 15 m/min | 1 ~ 15 m/min | 1 ~ 20 m/min |

Printed Matter Size | 200*300 mm ~ 390*1200 mm | 200*300 mm ~ 390*520 mm | 297*420 mm ~ 540*760 mm |

Laminating Film Thickness | 25 ~ 32 Mic | 17 ~ 32 Mic | 17 ~ 38 Mic |

Dimension of Reel (Film) | Φ75mm | Φ75mm | Φ75mm |

O.D Roll Film Dimension | Φ300mm | Φ340mm | Φ300mm |

Display Screen | Touch screen | Touch screen | Touch screen |

Heating Mode | Oil heating | Oil heating | Oil heating |

Auto feeding | Not supported | Dual air suction | Dual air suction |

Weight | 285 KG | 380 KG | 510 KG |

SF-390A Laminator

Heavy duty automatic laminating machine

- Auto feeding with air suction

- Pneumatic auto separation

- The anti-curl bar allows thin film laminates to be flat

- Mirror chrome heating roller

- Thermal or Cold laminating

- Touch screen display system

- Digital foiling

- 2 rolls film installation

- Adjustable electric hydraulic pressure system

SF-540A Laminator

Compact and reliable 540mm laminating machine

- Auto feeding with air suction

- Heavy duty construction

- 20m/min laminating speed

- Mirror chrome heating roller

- Thermal or Cold laminating

- Touch screen display system

- Digital foiling

- Adjustable electric hydraulic pressure system

- Large feeding volume, 2500 sheets, 200gsm paper

More Reliable Print Finishing Machines

Sunfung has a diverse range of print finishing solutions like the automatic laminating, label cutting, and card cutter, etc. Each of our print finishing products is manufactured to handle the most demanding conditions in this industry.

Flatbed Cutting Plotter

Clean and accurate cuts in a wide array of materials

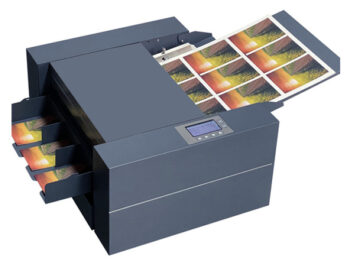

Automatic Card Cutter

Automatic friction feeding, 40 sheets, 250gsm feed tray

SF-LC34 Label Cutter

Auto feeding with hopper capacity up to 100 sheets or 18mm thick

Heavy duty & Automatic Print Finishing Products Supplier

Sunfung hold over 10 years manufacture and supply heavy duty and automatic print finishing products in China, include the automatic laminators, business card cutters, flatbed cutting plotter etc. We serviced global customers in USA, Germany, UK, France, Spain, Italy, Australia, Finland, Korea, etc

Annual Sales

Plant Area

Been Sold

Global Clients

Sun-Fung Factory Tour

Sunfung’s reputation comes from our consistent delivery of high-grade print finishing products that accomplishes nearly all of our clients’ requirements. Our capabilities in delivery quality print finishing products come from our strict QC management system, production lines, and material screening process.

What You Will Get During Manufacturing

Custom

Packaging

Ultrasonic

Washing

Measurement Instrument

Rotary

Post-curing Ovens

Clean Room

Manufacturing

Our Manufacturing Capability

To guarantee a suitable method in crafting your print finishing products, we review your requirements and provide a comprehensive consultation. Sunfung utilizes an advanced compression molding process to manufacture all of our print finishing products. Our team can also use the injection and transfer mold process for specific products. Below are other capabilities we can achieve when producing our print finishing products

Quality Assurance in Every Step

All of our print finishing products go through careful inspection and testing during the production process to guarantee they arrive at your address in excellent condition.

Incoming Quality Inspection

We implement a screening process when looking for raw material suppliers based on material conditions and consistency on the delivery date. Our team also checks every component delivered from our partnered suppliers to ensure they are free of any defect before we utilize them on our print finishing production process.

QC Checking

Our Quality & Control office allows us to monitor, test, and control the outcome of our print finishing products during the manufacturing process. Testing methods let us determine the machine appearance, safety check, assembly check, working test, Plug to confirm and accessories. Through our findings, we can correct any issues on our manufacturing process or find room for improvement.

Packaging & Delivery

Each print finishing product is given a comprehensive inspection before placing them within our packaging and shipping them out. We can even provide a clear image of your orders before we send them out to give you the ease of mind that your print finishing solutions are in good condition as they make their way to your business.

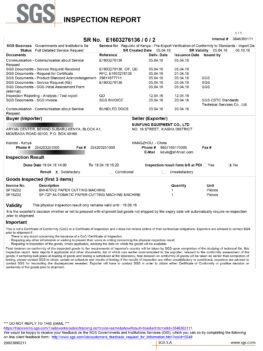

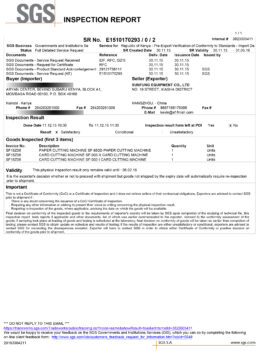

Certificated for Your Trust

With over 10 years’ experience in the manufacturing market in China, we pride ourselves at having the most experienced technicians and experts around. Most of our products have CE certification, with SGS inspection done before sending our products according to the customer’s request.

Why Choose Us

Our Core Value is “Make out the stable quality print finishing products, satisfy global customers demand in long-term for a win-win business cooperations”

Long Term Cooperation

We treat every customer for a long-term partner. So a win-win cooperation is sustainable

Fast Service

All parts within warranty or you buy can be sent out within 72 hours by air

Quality Control

We work with SGS and other 3rd party to guarantee machines quality over 10 years

Professional Customer Support for Your Project

Kevin Zhou

Sales Director

Rebecca Wang

QC Engineer

Irene Zhou

Sales Manager

Luke Si

Chief Engineer

Emy Chen

Sales Manager

What Does Our Client Say

Boost Your Business with Sun-fung

Sunfung

Copyright © 2012-2022, Sunfung Technology Corporation Ltd. All rights reserved.